direct drive motor vs belt

Direct drive is definitely better in terms of noise wash performance and power consumption. Belt drive needs a tension method and takes up more space.

What Is Better Direct Drive Motors Or Belt Drive Motors In A Washing Machine Quora

The Pioneer PLX-1000 is the best direct drive turntable in 2022.

. Direct Drive Motors are generally used in washing machines and is much than belt rive motors. The main difference of this directly driven compressor type is that they are no intermediary links between the belt and the pulley system. They also dont tend to have as many features as direct drive motors.

Would I be able to run the drivers at a lower power setting if I used gearing. Belt drive washing machines are mostly appreciated for their budget-friendly prices. Here a direct drive washer is 38 costlier than a belt-drive model.

Direct drive has less vibration and takes up less space. Direct drive pumps are mechanically simpler than belt drive pumps. Instead it has a crankshaft joined straightaway to the motor.

Machined steel pulleys and a link belt will lessen vibration. Over time a belt drive may need to be replaced. It is cheap and works well.

However a belt drive fan has power transmission loss due to the friction between the belt and sheaves and due to the drive shaft bearings. As a result the vibration damping is superb and the sound is stunningly transparent. Advantages of a direct drive compressor.

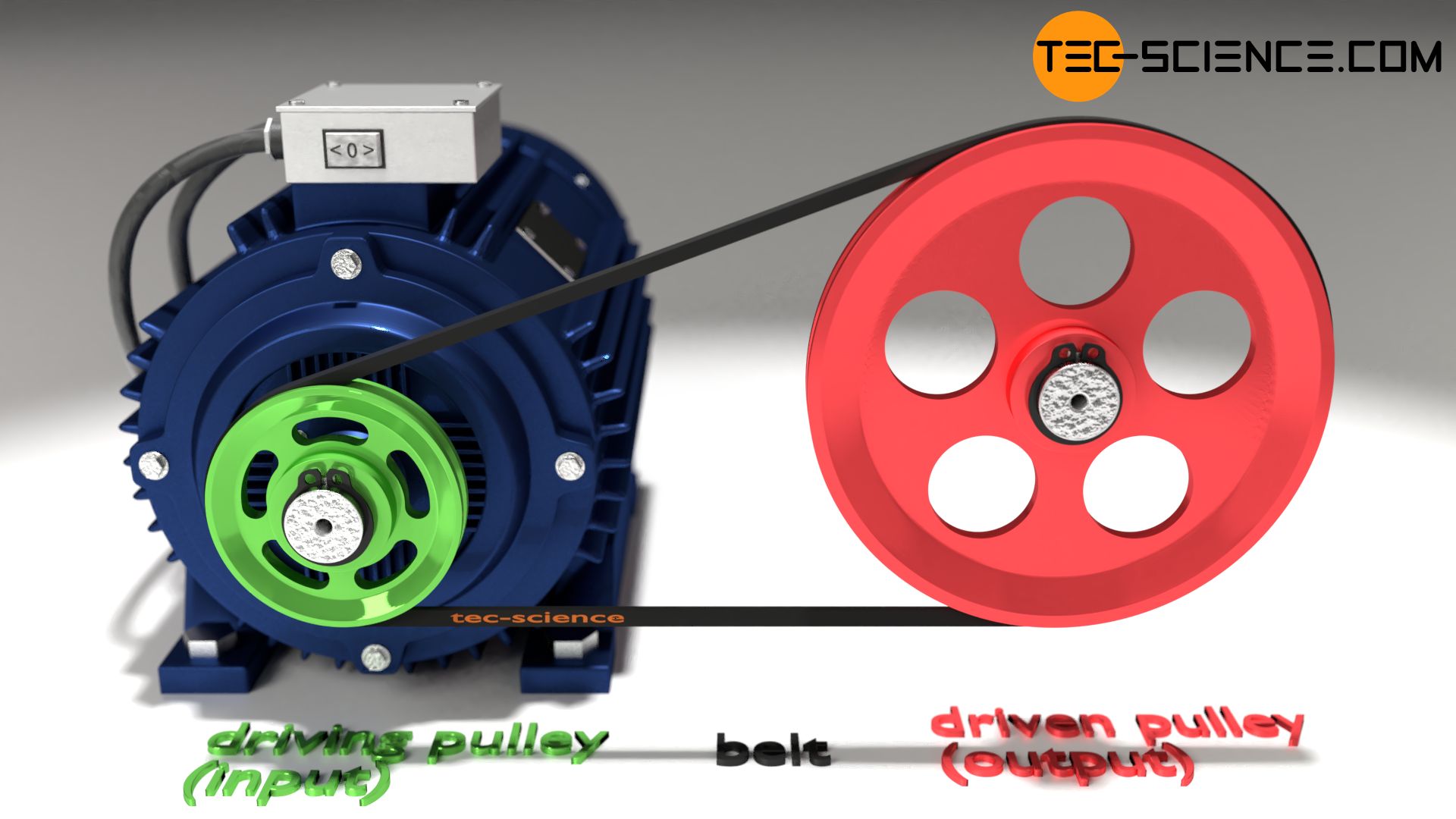

From a distance they can appear similar to an enclosed belt drive but upon further inspection the motor is too close to the hanger for that. They can absorb significant amounts of shock and vibration and eliminating the need of gearboxes speed and torque shifts are made possible by adjusting the size of the pulleys in the belt drive system. As energy costs increase it has become desirable to transition to a more efficient means of driving fan systems.

In summary price and the fact that belt drive motors are not attached directly to the turntable are the two biggest differences. For instance the belt will need to be changed and parts need oiled. This is the Arduino Code.

Putting a higher speed motor in a reduction like this allows for better efficiency better heat dissipation and better low end torque than hubs and direct drives but doesnt have many of the other advantages or disadvantages. We feel that if you can get those two right then in almost all cases the belt drive will outperform the direct drive for sheer musical enjoyment. But with direct drive you definitely run the risk of engine noise getting on your platter and being picked up by the stylus as a background rumble.

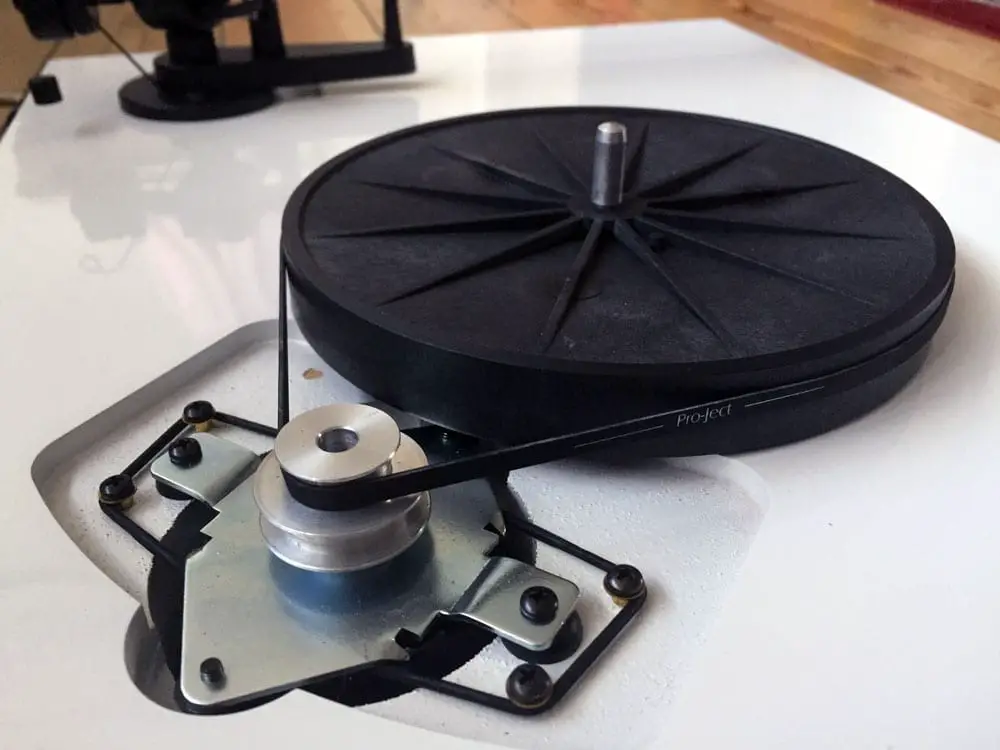

In a force feedback system rapid motor direction changes are common. You will have less chance of motor noise getting picked up by your stylus and the speed should be perceived as more pure. It is called a belt drive because the mechanism used to turn the platter is composed of an electric motor attached to a belt which attaches to the underside of the platter causing it to rotate.

Direct drive fans have no power transmission loss since the propeller is directly connected to the motor shaft. Enjoy Same Day or Next Working Day Delivery on Engine Belt. If the pulley loosens it.

The obvious advantage of direct drive is simplicity. The second most distinct difference between the two is price. A well-designed and manufactured belt-drive turntable remains the de facto choice for Hi-Fi audio enthusiasts while direct-drive offers the level of control and durability desired for turntablism.

Belt drive allows a multi-pulley that will thus allow speed change. Therefore it is a wrong view that there is no energy loss in direct drive. They both are different in how the motor spins and their design differs from each other.

Belt drive turntables also have a slightly less accurate playback speed than direct drive turntables. A belt drive turntable is the traditional format you are probably most used to seeing and using. The motor function of the direct drive is different from the belt drive.

On the other hand belts tend to break every so often meaning that you tend to perform more repairs. In a force feedback system rapid motor direction changes are common. However the bearings and other.

The belt drive helps to better isolate the platter from the engine because the only connection is the rubber belt. Assuming speed reduction a direct drive low speed motor will have a lower efficiency lower power factor bigger size and higher cost as compared to belt driven higher speed motor. Both are created for different audiences.

Ad Wide Range of Engine Belt at Unbeatable Prices. This style has been popular for decades. Also they do not have as much longevity as direct drive motors.

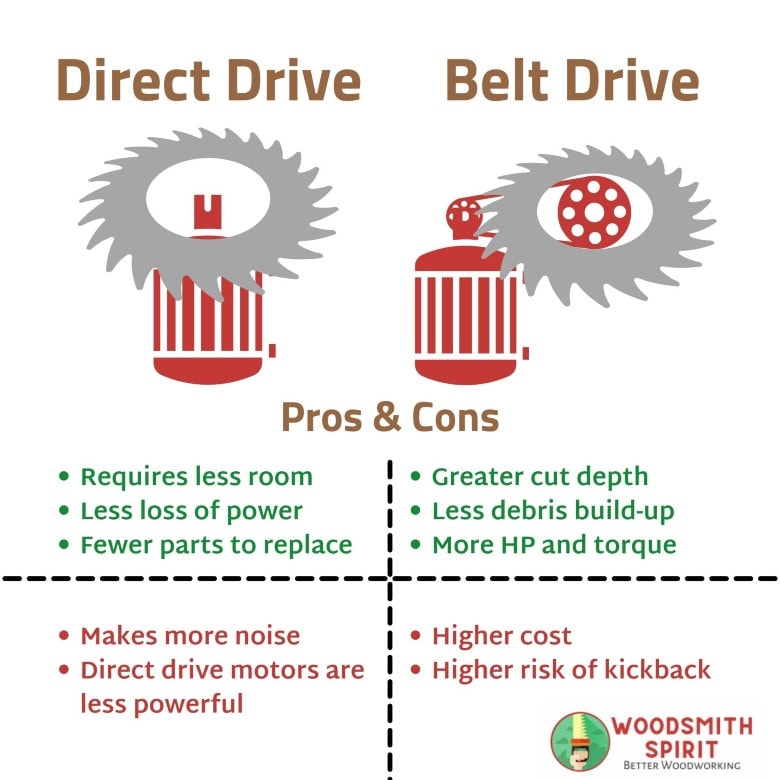

Nonetheless the reason behind the increasing costs is not just direct-drive motor technology. For instance a direct drive saw can only cut wood about two inches thick. Of course belts themselves have plus and minus points as pointed out by mvcjr and jbartos.

Vibration can be a problem. Although the initial cost is high if you keep the washing machine for a couple of years then the extra cost can be recovered easily. The next easiest options are belt drive or a geared stepper motor.

A good example is the Music Hall MMF-13. Motors in belt drive applications can experience significantly different load scenarios compared to direct. The direct drive is mainly created for the DJs and designed to work with two turntables while the belt drive doesnt possess such functions.

Due to the simplicity of direct drive pumps the design is more compact which is useful when used in tight areas. Edison123 Electrical 6 Nov 03 2315. Belt drives apply greater load on the main shaft of the machine it has a direct effect on the life time of bearings shaft misalignment and as a result oil leakage and more vibrations.

The belt drive motor would have to spin 20 times faster than the direct drive motor to match the direct drive systems ability to produce detail. Direct drives requires less space in comparison to belt drives so smaller machines. Given that direct-drive engines are the newest technology they tend to have more features.

Oct 2 2014. This situation is obviously very rare. While torque isnt necessarily a critical quality it can be a deal-breaker for some.

This kind of pump mounts directly on the motor or engine has few moving parts and is the most cost-effective option. Another drive way is belt driven which allows the rotating speed of the rotor to be changed by pulleys of different diameters. But that is not to say there arent some great sounding direct-drive turntables on the market.

The belt drive motor would have to spin 20 times faster than the direct drive motor to match the direct drive systems ability to produce detail. But if you are tight on budget then a belt drive-based washing machine is the only option. While belt drive turntables are incredibly popular they have a lower torque than direct drive turntables.

The belt driven system. A direct drive system simply makes these changes and. However belt drive saws also require more maintenance because of the multiple working parts.

Video of the machine running. Direct drive in the true sense means that the motor is directly connected with the rotor Coaxial which has the same speed. Direct drive pump.

Even when belts are properly tensioned and the sheaves are aligned the power transmission loss of a belt drive fan. Belt drive motors are a less costly alternative to direct drive. As direct drive washers are more efficient in their function they remain the top choice for manufacturers in.

The belt also requires proper maintenance and wear and tear is much more in belt drive than in Direct Drive Motors. The bottom line. It has everything a professional DJ might want including a high-torque direct drive motor multi-pitch control replaceable power and audio cables and a streamlined design.

As you might have guessed the primary difference between a direct drive motor and a belt drive motor is that the former does not utilize a belt. Belt Drive motors are used to transmit power over much larger distances with considerable reduction in power. Would a geared or belt drive help reduce the vibration in the mechanism.

Table Saw Motor Drive Types And Specs Explained Guide

Direct Drive Vs Belt Drive Washing Machines Which Is Better Survival Freedom

Chain Drive Vs Belt Drive Vs Shaft Drive Motorcycle Drivetrain Explained

Direct Drive Vs Belt Drive Washing Machine Which Is Better Kitchenarena

Direct Drive Vs Belt Drive Washing Machine Which Is Better Kitchenarena

What Is Better Direct Drive Motors Or Belt Drive Motors In A Washing Machine Quora

How Does A Belt Drive Work Tec Science

Direct Drive Vs Belt Drive Turntables What S The Difference Sound Matters

Difference Between Direct Drive And Belt Drive Washing Machine Youtube

Direct Drive Vs Belt Vs Gear Racing Wheels Which Should You Buy

The System Benefits Of Direct Drive The Comparison Tab Tv

Direct Drive Vs Belt Vs Gear Racing Wheels Which Should You Buy

Direct Drive Vs Belt Drive Washing Machines Which Is Better Survival Freedom

Types Of Belt Drive Material Applications Advantages Disadvantages Engineering Learn

Belt Drive Vs Direct Drive Laundry Youtube

What Is Better Direct Drive Motors Or Belt Drive Motors In A Washing Machine Quora

What Is Better Direct Drive Motors Or Belt Drive Motors In A Washing Machine Quora

What S The Difference Between A Hub Drive And A Belt Drive Electric Sk Electric Board Co

Direct Drive Vs Belt Drive Washing Machine Which Is Better Kitchenarena